The key bottleneck restricting the development of advanced equipment is to meet the requirements of advanced resin composite materials with high strength, high temperature resistance and light weight. At present, such a difficult problem is expected to be solved. The reporter learned from East China University of Science and Technology that the first domestic polymer material genome research and development platform (AI plus polymer software platform) developed by Professor Lin Jiaping’s team was recently released in Shanghai.

The software is called "polymer version of ChatGPT", which contains the first database of resin structure and properties and chemical reaction between groups in China. Users only need to input the resin structure, they can quickly obtain its mechanical, thermal and dielectric properties, and can also make performance prediction and high-throughput screening through this software, so as to develop high-performance polymers and their composites with faster efficiency and lower cost.

"The research and development of new materials has entered the era of intelligent manufacturing from the era of trial and error of scientists." Lin Jiaping introduced that in the past, it often took 2-3 years or even longer for a new material to go from design, experiment to productization. Now, relying on this "polymer virtual laboratory", R&D personnel can find the optimal solution of structural design and formula optimization only through 2-3 iterations, and the experimental time is greatly reduced. The team will join hands with the industry to promote the development of AI plus polymer research paradigm to the whole industry chain.

Powerful database and forecasting system lead the industry.

What are the highlights of the AI plus polymer software platform? Lin Jiaping introduced that as an important achievement in the cross field of AI and digital technology and polymer materials, a powerful database is an important support of the platform and can be described as the cornerstone of material genetic engineering. The first database of resin structure and properties and chemical reaction between groups established by the team in China contains nearly 150,000 performance data of more than 34,000 polymers and nearly 1.4 million chemical reaction data of 58,516 basic reaction templates.

It is worth mentioning that these data mainly rely on dozens of graduate students and undergraduates in the past three years, especially during the epidemic, to standardize, enter and store them one by one. Based on the database, the team created a machine learning prediction model for more than ten properties of polymers, and built a research and development platform for polymer materials genome, which has multiple functions such as data retrieval, performance prediction and formula optimization.

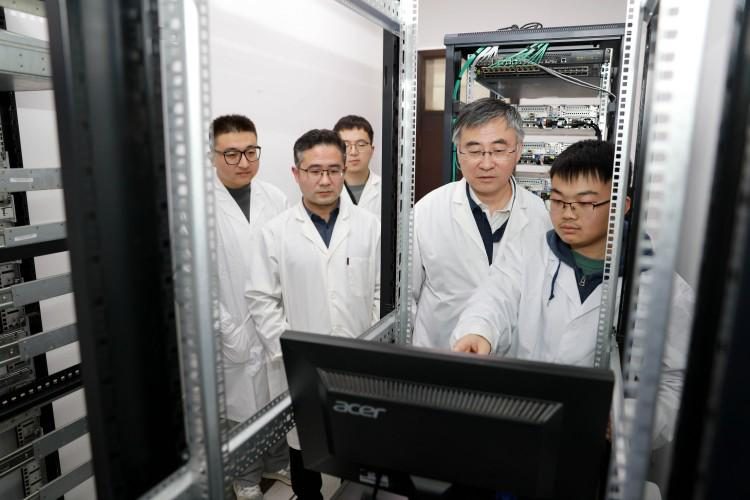

The reporter saw in the team’s live demonstration that when users use the AI plus polymer software platform to predict the performance of polymer materials, they only need to click "Draw Structure" first, input the drawn strings of epoxy resin and curing agent into the corresponding input boxes, and then click "Start Prediction". After a few seconds, the page will return to the performance prediction data of epoxy resin calculated in the background.

So, how does this software compare with foreign counterparts? For example, Gao Liang, one of the team members and a special researcher at East China University of Science and Technology, has similar software in the United States and Japan. However, in terms of database richness, prediction accuracy and functional diversity, AI plus polymer software platform is superior. "Our goal is to seize the opportunity of digital and artificial intelligence to change the new material industry, develop high-performance polymers and their composites with faster efficiency and lower cost, and realize the original innovation and intelligent manufacturing of polymer materials." Gao Liang said.

The research and development of new materials has entered the era of "intelligent manufacturing" from the era of experience "trial and error"

The development of AI plus polymer software platform can be described as a sword after ten years. It is reported that since 2011, Lin Jiaping’s team has seized the frontier field of material research-material genetic engineering to start related work.

With the cooperation of gene combination screening and AI tools, the team developed a series of advanced composite matrix resins. For example, the curing temperature is less than 300℃, the 5% thermal decomposition temperature is more than 650℃, and the glass transition temperature is more than 600℃. For another example, a new type of high-temperature resistant and high-toughness poly (alkynyl imide) resin is superior to polyimide in processability, heat resistance and interface properties, and its mechanical properties are equivalent to polyimide. Related new resins have been evaluated by many aerospace institutes for the performance of composite materials and components.

"The AI plus polymer software platform is like a polymer virtual laboratory. The virtual design of the platform and the method of high-throughput prediction will greatly improve the research and development efficiency." Lin Jiaping introduced that at present, the platform has been tried in more than ten enterprises such as Shanghai Huayi Group Resin Factory, Shanghai Aerospace Eighth Institute, Jinfei Carbon Fiber Technology and Jinshan Petrochemical Institute, and will be used to the public.

Author: Wu Jinjiao

Editor: Chu Shuting

Editor in charge: Fan Liping

Photo: East China University of Science and Technology

* The exclusive manuscript of Wenhui, please indicate the source.

关于作者