1. Main features of digital intelligent factory

2. Construction scheme of digital intelligent factory

2.1. Big Database and Cloud Computing

2.2. Information system construction

2.3 Business systems (OA system, BPS system, MES system, SAP system, PLM system, parts tracing system, CRM system, QMS system, SCM system, TMS system, WMS system)

2.4 wisdom scheduling

2.5 intelligent logistics

2.6 Smart scene

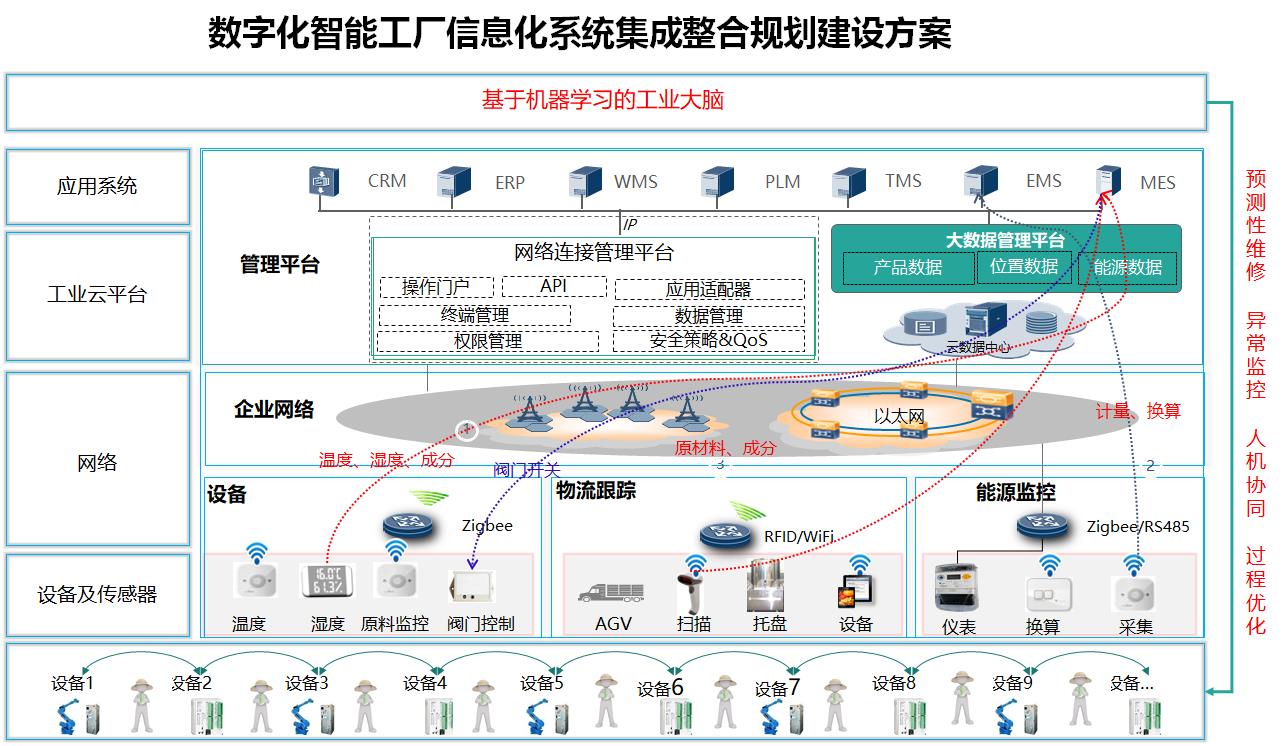

2.7 Planning diagram of digital intelligent factory information system

① Intelligent energy management: real-time perception, monitoring, early warning and control of energy consumption, and real-time optimization of energy efficiency.

② Intelligent supply chain: build a network supply chain, and control and optimize the logistics, capital flow and production cycle in the supply chain system composed of suppliers, manufacturers, distributors and final customers, so as to reduce the logistics cost and shorten the production cycle.

③ Intelligent equipment: the equipment has the functions of perception, acceptance, self-discipline and intelligence.

④ Intelligent production: the deep integration of informatization and production realizes the closed-loop optimization management of all business processes at three levels: production operation, production management and management decision.

① Virtual reality (modeling and simulation technology); (One of the two major traction technologies facing the future)

② Artificial intelligence (optimization and intelligent technology): (one of the two major traction technologies facing the future)

③ Industrial intelligent robot; (one of the two major hardware)

④ Industrial network security; (one of the two major hardware)

⑤ Industrial automation; (one of the two systems)

⑥ Industrial Internet of Things; (based on the three foundations of distributed connection)

⑦ Cloud computing; (based on the three foundations of distributed connection)

⑧ Big data (cloud computing and data mining technology); (based on the three foundations of distributed connection)

Pet-name ruby visual system (one of the two systems)

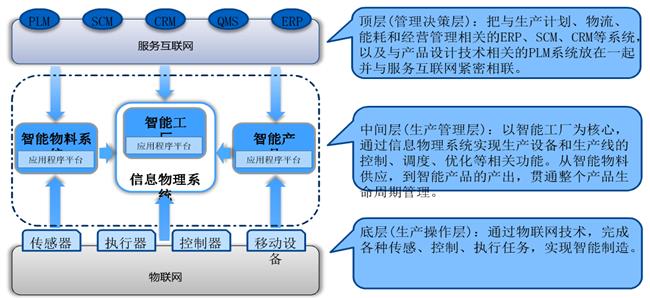

Three-tier architecture of digital factory

① Data collection and analysis: collection and analysis of energy information.

② Prediction: the difference between energy efficiency bottleneck and energy consumption bottleneck.

③ Coordination and optimization: intelligent equipment coordination and optimization (intelligent) management and operation.

④ Efficiency improvement: improve energy efficiency and save energy.

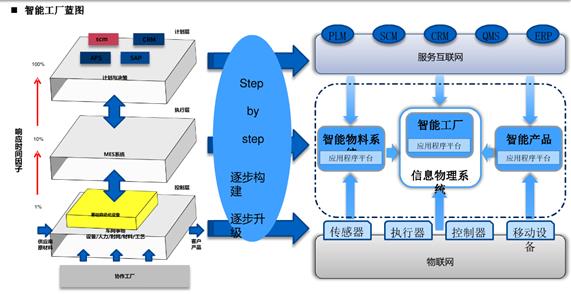

Smart factory blueprint

Informatization integration of digital factory

In short, digital intelligent factory should not only realize automation, transparency, visualization and lean production process, but also realize closed-loop integration with production process in product inspection, quality inspection and analysis, production logistics and other links. Information sharing, on-time delivery and collaborative work should also be realized among multiple workshops in a factory. The construction of digital factory fully integrates information technology, advanced manufacturing technology, automation technology, communication technology and artificial intelligence technology.

关于作者